Optimize Fabrication Workflows with DXNest

DXNest is dedicated to transforming fabrication processes through automation. Our mission is to enhance efficiency by reducing prep time, cutting waste, and automating labor-intensive tasks. We are committed to innovation, precision, and supporting manufacturers in achieving faster, more accurate production cycles.

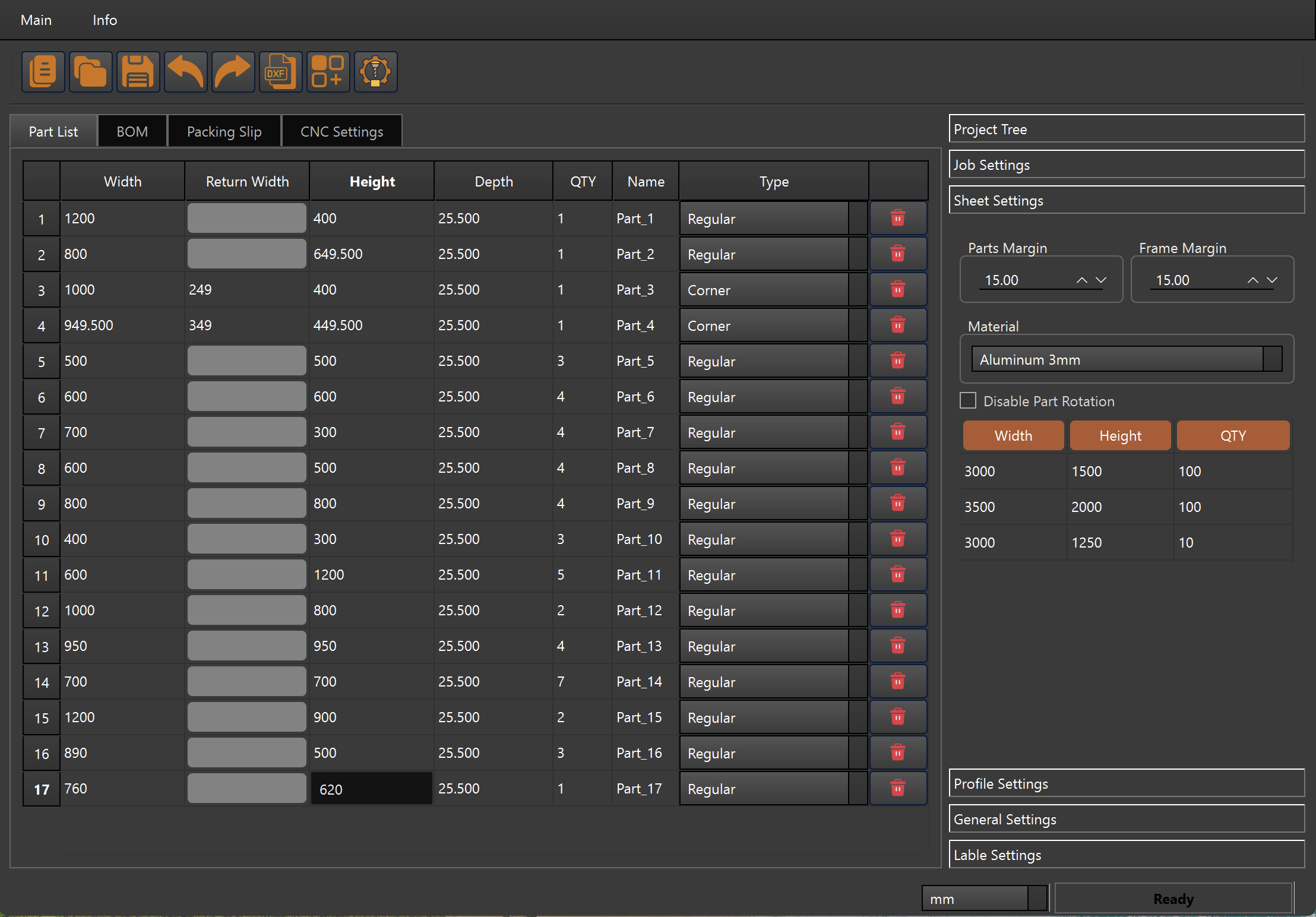

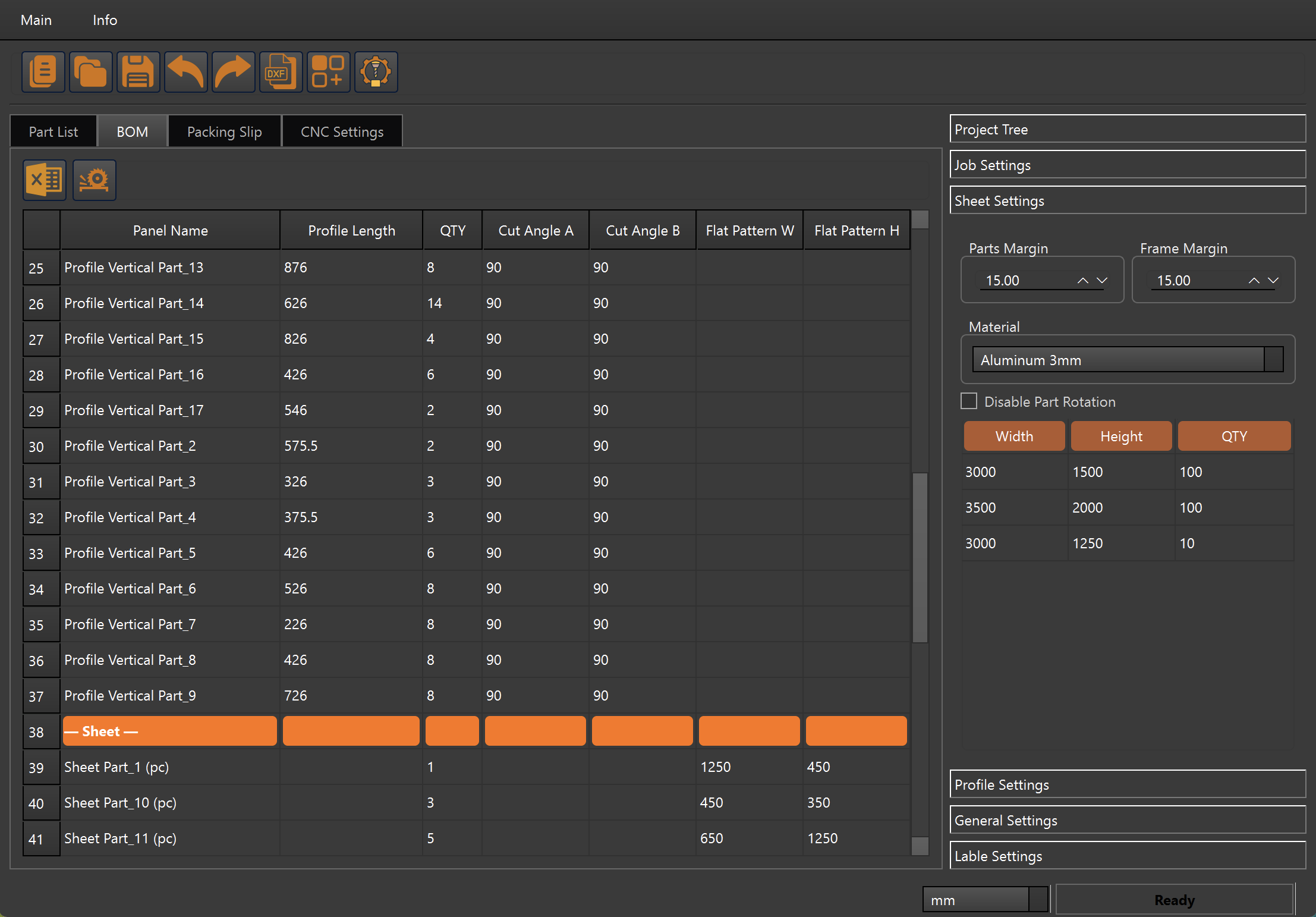

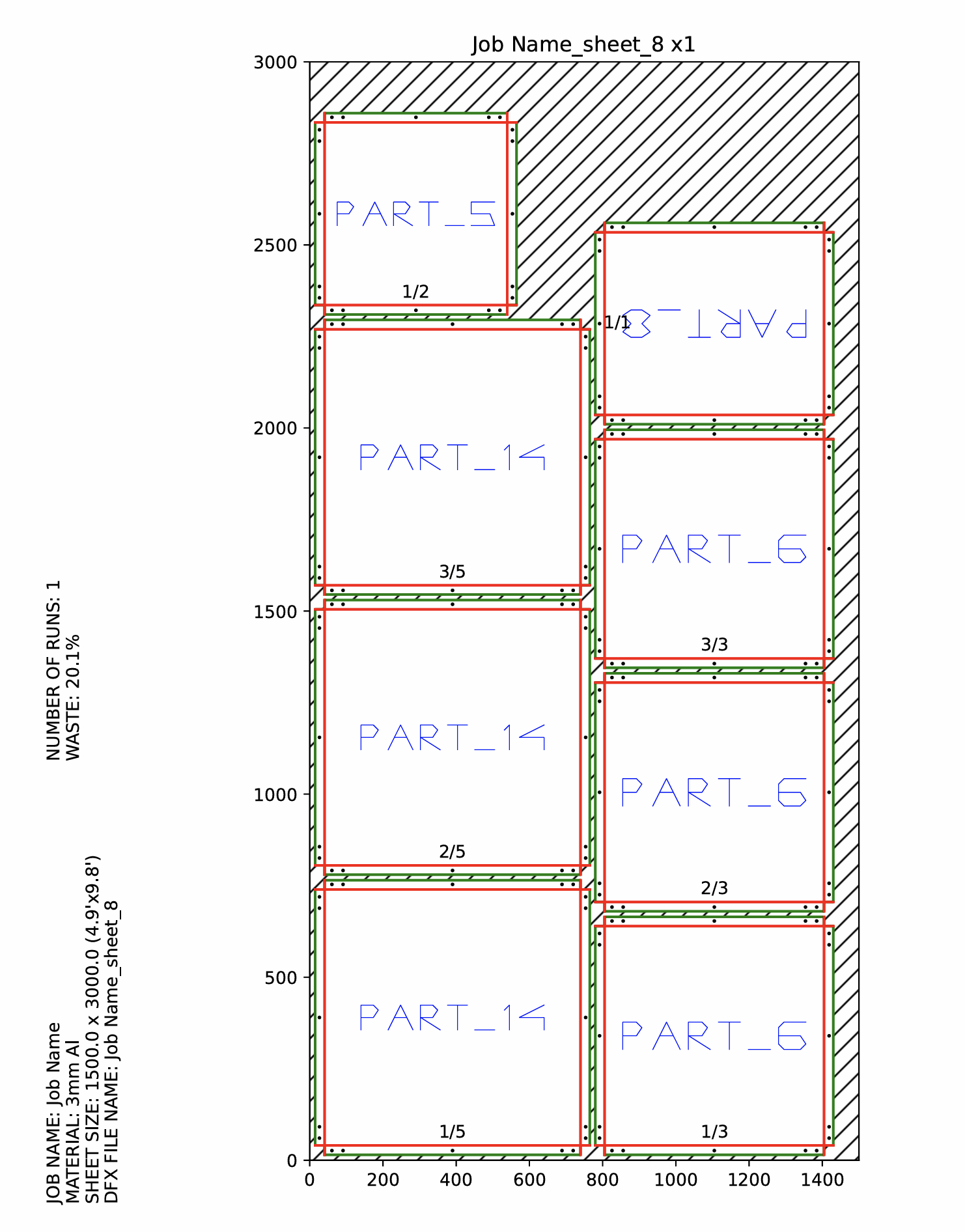

DXNest Interface Preview

Panel list view where panel dimensions, quantities, and types are defined before nesting.

BOM and sheet settings view combining project tree, sheet formats, and material configuration.

Example of a DXNest nesting layout showing multiple panel types placed on one sheet with highlighted waste area.