Automatic DXF Processing

DXNest automatically reads and validates DXF files, removing manual prep work from the workflow.

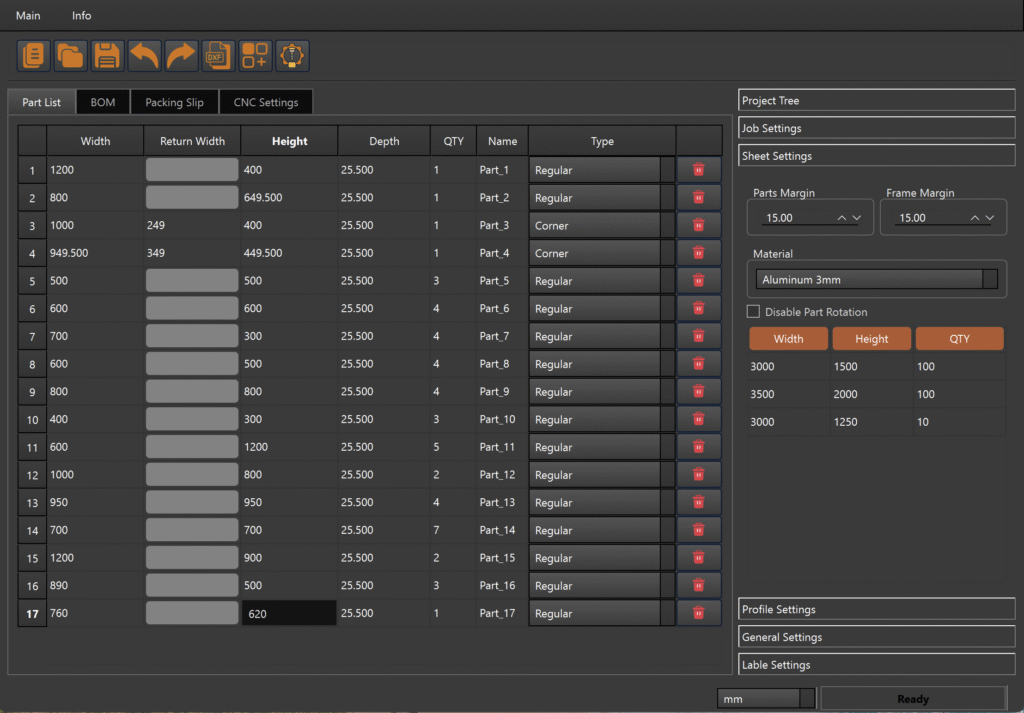

DXNest PanelBuilder Features

From fabrication to automation – we do it all

DXNest automatically reads and validates DXF files, removing manual prep work from the workflow.

Generates precise panel geometry from drawings or parameters, ready for fabrication.

Optimizes part layouts on sheets to minimize scrap and improve material utilization.

Creates ready-to-run CNC programs for fabrication lines in a few clicks.

Works with multiple sheet sizes and available stock, following real production constraints.

Automatically builds detailed BOMs for panels, hardware, and materials.

Handles thousands of parts with parallel processing and smart task distribution.

Generates packing slips, labels, PDFs, Excel reports, and production summaries automatically.

About DXNest

DXNest is an engineering-driven CAD/CAM platform created specifically for aluminum facade and sheet-metal fabrication.

It automates panel geometry, nesting, CNC programs, and documentation, reducing manual work and eliminating repetitive tasks for engineers and production teams.

Designed by mechanical and facade engineers, DXNest reflects real production workflows, constraints, and standards used on modern fabrication lines.

DXNest has been implemented on real projects with thousands of panels, helping shops cut preparation time, reduce scrap, and deliver precise results consistently.

Frequently Asked Questions

DXNest is a specialized CAD/CAM solution for sheet-metal and façade fabrication. Here are answers to the most common questions about how it works and how it can be integrated into your workflow

DXNest is a CAD/CAM software system that automates the entire preparation process for sheet-metal and façade production. It reads parts from DXF drawings and Excel files, performs nesting on available sheet sizes, generates DXF layouts, CNC programs, Bills of Materials, packing slips, and material reports

DXNest is intended for façade engineering companies, metal fabrication shops, and manufacturers that work with aluminum or steel panels, cladding systems, and other sheet-metal components. It is especially useful when you have many similar parts and need to prepare nesting and CNC files quickly and accurately

You can use DXF drawings with panel contours and an Excel spreadsheet with project parameters, material types, thicknesses, quantities, and sheet sizes. DXNest automatically detects closed contours, builds a parts list, and prepares optimized nesting layouts based on the available materials

DXNest generates nested DXF layouts, CNC programs for cutting machines, Bills of Materials, packing slips, and detailed material usage reports in Excel and PDF formats. These documents can be used directly in production and for project documentation

Yes. You can define multiple sheet formats and their available quantities. DXNest will distribute parts between them to minimize waste. Material type and thickness are taken into account, so parts are always placed on the correct sheet

Yes. DXNest can be adapted to your specific fabrication standards, CNC formats, and reporting templates. We can help integrate the software into your current CAD and production workflow

You can contact us using the form below or send an email to contact@dxnest.io. We will schedule an online demonstration and discuss how DXNest can be applied to your current projects

If you work with sheet-metal panels, façade systems, or other standard production and want to reduce preparation time and material waste, DXNest can become a core part of your workflow. Send us your typical project example, and we will show how it can be processed in DXNest – from DXF drawings to nested layouts, CNC programs, and documentation